Land Rover Discovery: Manual Transmission - Transaxle / Diagnosis and Testing

PRINCIPLES OF OPERATION

For a detailed description of the Manual Transmission, refer to the relevant Description and Operation section in the workshop manual. REFER to: Manual Transmission (308-03 Manual Transmission/Transaxle, Description and Operation).

INSPECTION AND VERIFICATION

CAUTION:

Diagnosis by substitution from a donor vehicle is NOT acceptable.

Substitution of control modules does not guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

- If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new module/component.

- When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with an up-todate calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into account.

- Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

- Verify the customer concern

- Visually inspect for obvious signs of damage and system integrity

Visual Inspection

.jpg)

- If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step

- If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

- Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific customer complaint and carry out the recommendations as required

SYMPTOM CHART

NOTE:

Check the transmission fluid level prior to performing any further diagnosis.

.jpg)

.jpg)

.jpg)

SYMPTOM:

Synchronizer crashing or significant effort required when downshifting

POSSIBLE CAUSES:

- Gearshift mechanism internal failure

- Gearshift cables incorrectly installed

- Manual transmission internal failure

ACTION:

- Check the integrity of the gearshift mechanism

- Check the installation of the gearshift cables

- Install a new manual transmission

SYMPTOM:

Gear jumps out of engagement while driving

POSSIBLE CAUSES:

- Manual transmission internal failure

ACTION:

- Install a new manual transmission

SYMPTOM:

Gearshift linkage does not operate freely (stiff or partially seized)

POSSIBLE CAUSES:

- Gearshift mechanism internal failure

- Gearshift cables incorrectly installed

- Manual transmission internal failure

ACTION:

- Check the integrity of the gearshift mechanism

- Check the installation of the gearshift cables

- Install a new manual transmission

SYMPTOM:

Brief scratching noise during gear shifting

POSSIBLE CAUSES:

- Manual transmission internal failure

ACTION:

- Install a new manual transmission

SYMPTOM:

Fluid leak from the manual transmission housing

POSSIBLE CAUSES:

- Fluid filler plug not sealing

- Fluid drain plug not sealing

- Input shaft oil seal leaking

- Output shaft oil seal(s) leaking

- Selector shaft oil seal leaking

- Crankshaft rear seal leaking

- Clutch slave cylinder leaking

ACTION:

- Remove the fluid filler plug. Install a new sealing washer. Install the filler plug and tighten to the specified torque

- Remove the fluid drain plug. Install a new sealing washer. Install the drain plug and tighten to the specified torque

- Install a new input shaft oil seal

- Install a new output shaft oil seal as necessary

- Install a new crankshaft real oil seal

- Install a new clutch slave cylinder

SYMPTOM:

Clicking noises in reverse gear

POSSIBLE CAUSES:

- Manual transmission internal failure

ACTION:

- Install a new manual transmission

SYMPTOM:

Gear wheels banging when shifting

POSSIBLE CAUSES:

- Manual transmission fluid level low

- Clutch not disengaging completely when the clutch pedal is depressed

- Manual transmission internal failure

ACTION:

- Refer to the relevant section of the workshop manual and check the manual transmission fluid level. Top up as necessary

- Refer to the relevant section of the workshop manual and check the clutch system

- Install a new manual transmission

SYMPTOM:

Noises in the forward gears

POSSIBLE CAUSES:

- Manual transmission fluid level low

- Foul condition - Engine/transmission fouling body

- Engine/transmission flange bolts loose

- Manual transmission internal failure

ACTION:

- Refer to the relevant section of the workshop manual and check the manual transmission fluid level. Top up as necessary

- Check the integrity of the engine/transmission mountings

- Check the integrity of the engine/transmission flange bolts

- Install a new manual transmission

SYMPTOM:

Gears jump out of engagement

POSSIBLE CAUSES:

- Gearshift mechanism internal failure

- Gearshift cables incorrectly installed

- Manual transmission internal failure

ACTION:

- Check the integrity of the gearshift mechanism

- Check the installation of the gearshift cables

- Install a new manual transmission

SYMPTOM:

One of the gears (particularly reverse) cannot be selected

POSSIBLE CAUSES:

- Gearshift mechanism internal failure

- Gearshift cables incorrectly installed

- Manual transmission internal failure

ACTION:

- Check the integrity of the gearshift mechanism

- Check the installation of the gearshift cables

- Install a new manual transmission

SYMPTOM:

Unable to select first and second gears (third, sixth and reverse ok)

POSSIBLE CAUSES:

- Gearshift mechanism internal failure - Broken selector pin in gate guide

- Gearshift cables incorrectly installed

- Manual transmission internal failure

ACTION:

NOTE:

DO NOT install a new manual transmission for this fault.

- Install a new gearshift mechan

SYMPTOM:

Gearshift linkage has excessive play

POSSIBLE CAUSES:

- Gearshift mechanism internal failure

- Gearshift cables incorrectly installed

ACTION:

- Check the integrity of the gearshift mechanism

- Check the installation of the gearshift cables

SYMPTOM:

Clutch slipping

POSSIBLE CAUSES:

- Clutch pedal not returning fully

- Clutch controls hydraulic fault -

- Fluid leak, air ingress, etc

- Clutch slave cylinder not returning fully

- Clutch friction plate excessively worn

- Clutch friction plate contaminated with oil

- Clutch friction plate overheated

- Clutch pressure plate warped/failed

ACTION:

- Check the operation of the clutch pedal

- Check the clutch controls for leaks, air ingress, etc

- Install a new clutch assembly

- Investigate the source of the oil leak.

Rectify as necessary. Install a new clutch assembly

SYMPTOM:

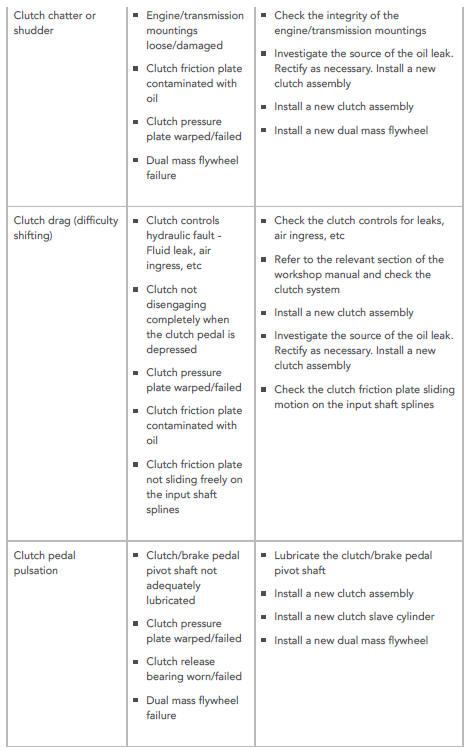

Clutch chatter or shudder

POSSIBLE CAUSES:

- Engine/transmission mountings loose/damaged

- Clutch friction plate contaminated with oil

- Clutch pressure plate warped/failed

- Dual mass flywheel failure

ACTION:

- Check the integrity of the engine/transmission mountings

- Investigate the source of the oil leak.

Rectify as necessary. Install a new clutch assembly

- Install a new clutch assembly

- Install a new dual mass flywheel

SYMPTOM:

Clutch drag (difficulty shifting)

POSSIBLE CAUSES:

- Clutch controls hydraulic fault - Fluid leak, air ingress, etc

- Clutch not disengaging completely when the clutch pedal is depressed

- Clutch pressure plate warped/failed

- Clutch friction plate contaminated with oil

- Clutch friction plate not sliding freely on the input shaft splines

ACTION:

- Check the clutch controls for leaks, air ingress, etc

- Refer to the relevant section of the workshop manual and check the clutch system

- Install a new clutch assembly

- Investigate the source of the oil leak.

Rectify as necessary. Install a new clutch assembly

- Check the clutch friction plate sliding motion on the input shaft splines

SYMPTOM:

Clutch pedal pulsation

POSSIBLE CAUSES:

- Clutch/brake pedal pivot shaft not adequately lubricated

- Clutch pressure plate warped/failed

- Clutch release bearing worn/failed

- Dual mass flywheel failure

ACTION:

- Lubricate the clutch/brake pedal pivot shaft

- Install a new clutch assembly

- Install a new clutch slave cylinder

- Install a new dual mass flywheel

DTC INDEX

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.