Land Rover Discovery: Side Panel Sheet Metal Repairs Side Panel (G1770901) - Installation

Land Rover Discovery (2009–2016) Service Manual / Body / Body Repairs and General

Information / Side Panel Sheet

Metal Repairs

Side Panel (G1770901) / Side Panel Sheet

Metal Repairs

Side Panel (G1770901)

- Installation

Installation

NOTE:

Make sure that a zinc rich primer is applied to any bare metal surfaces.

- Dress the flanges where necessary

- Clean and prepare the panel surfaces.

CAUTION:

This step requires the aid of another technician as the side panel is heavy.

- Offer up the new side panel and clamp into position. Check alignment, if correct, proceed to next step, if not, rectify and recheck before proceeding.

NOTE:

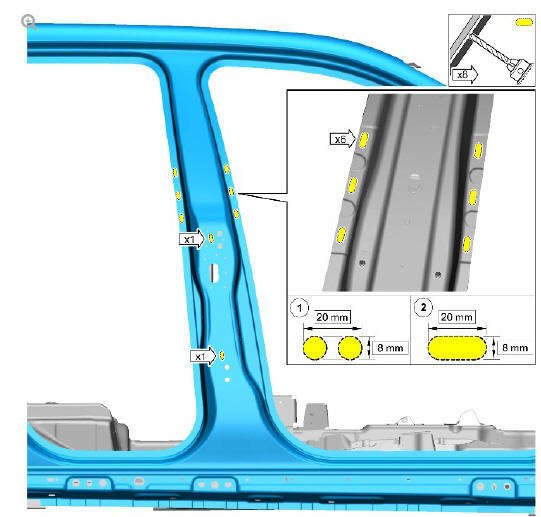

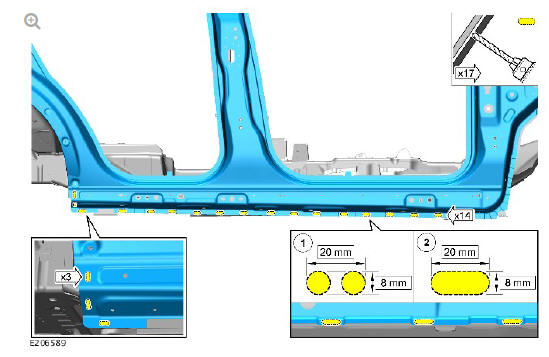

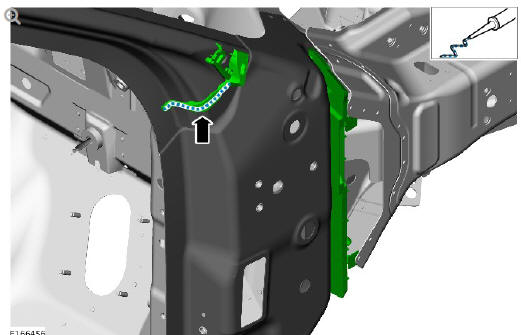

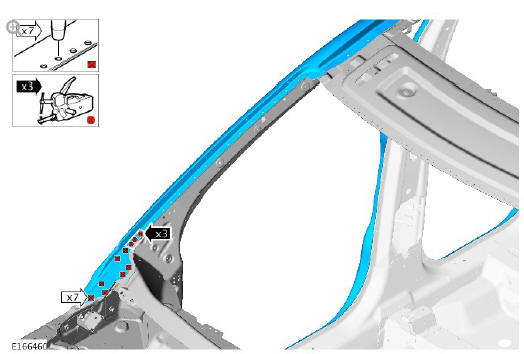

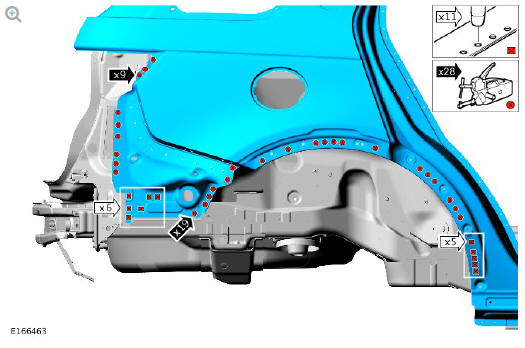

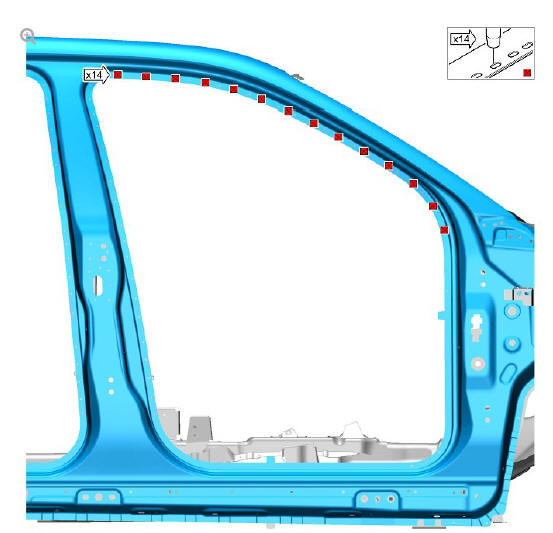

Follow steps 1 and 2 as shown to cut the MIG braze slots.

- Mark the position and cut slots in the new side panel where the Metal Inert Gas (MIG) braze slot welds are to be installed as indicated.

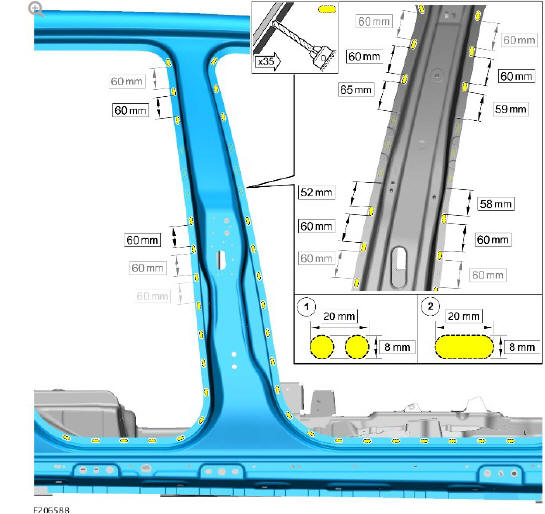

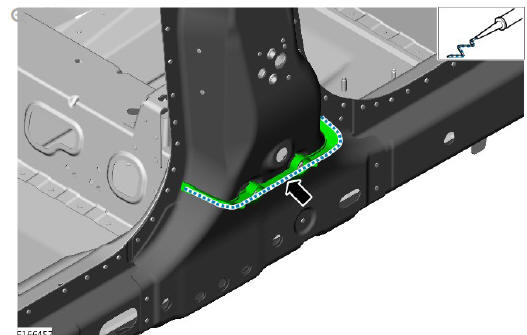

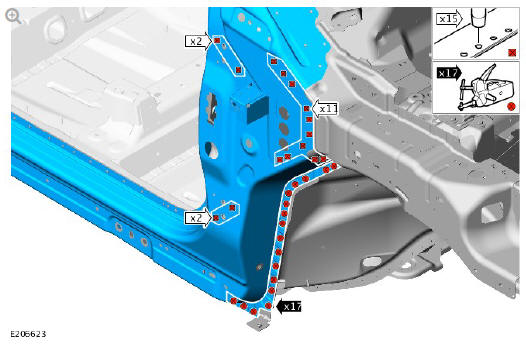

NOTE:

Follow steps 1 and 2 as shown to cut the MIG braze slots.

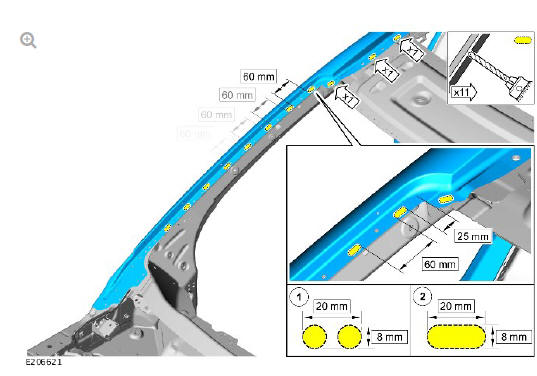

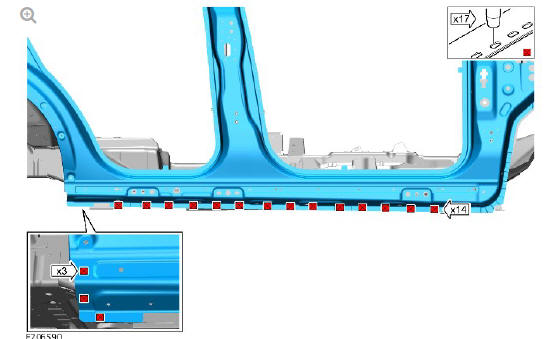

- Mark the position and cut slots in the new side panel where the MIG braze slot welds are to be installed as indicated.

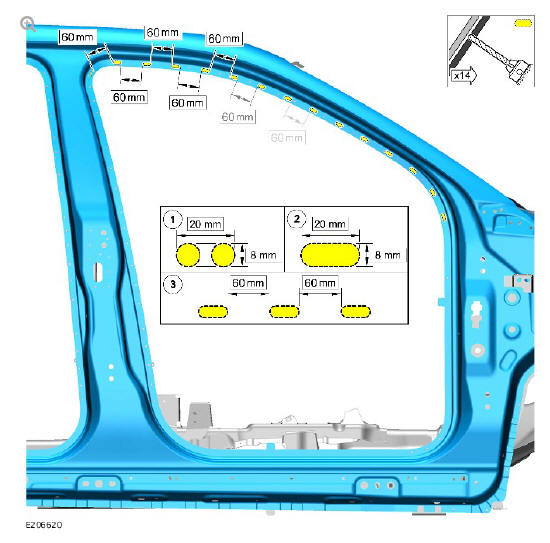

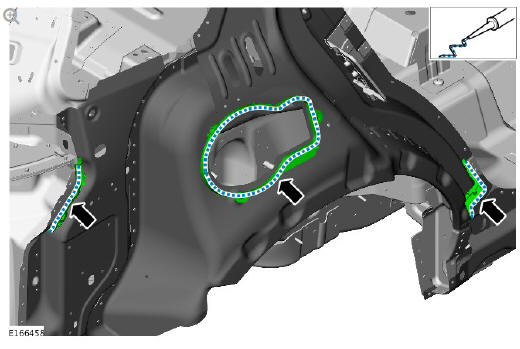

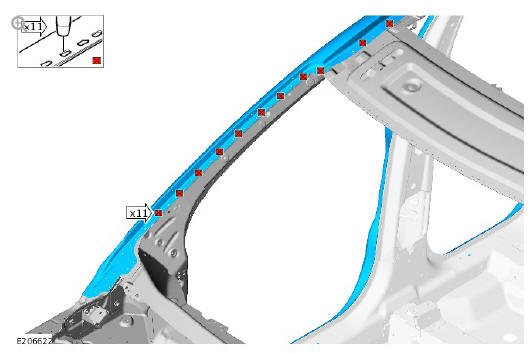

NOTE:

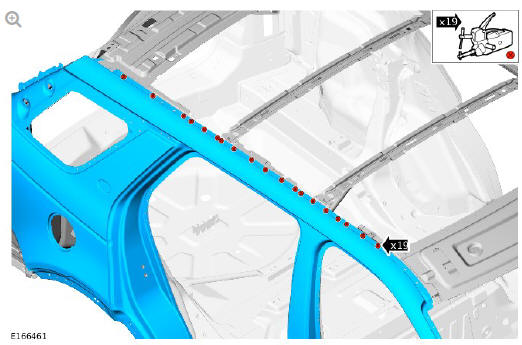

Follow steps 1 to 3 as shown to cut the MIG braze slots.

- Mark the position and cut slots in the new side panel where the MIG braze slot welds are to be installed as indicated.

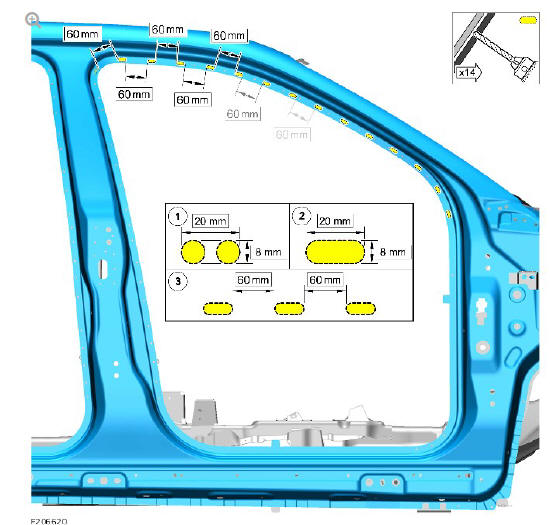

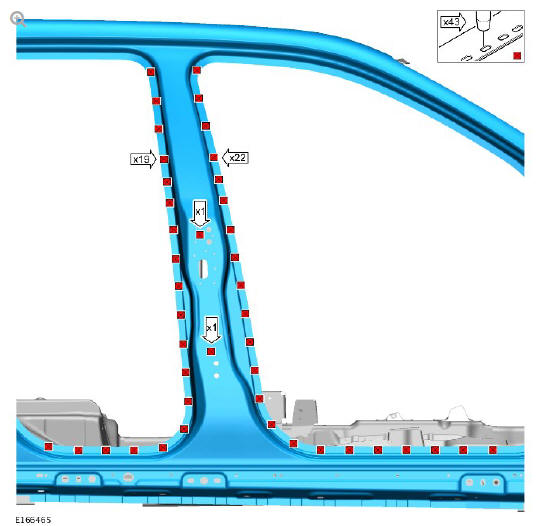

NOTE:

Follow steps 1 to 3 as shown to cut the MIG braze slots.

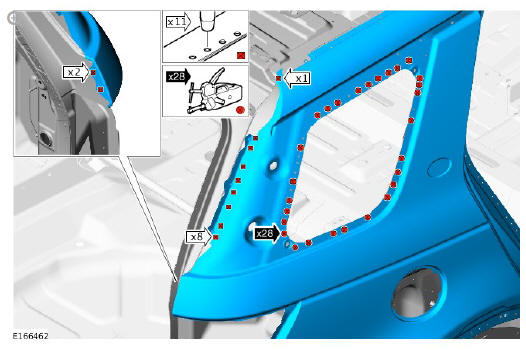

- Mark the position and cut slots in the new side panel where the MIG braze slot welds are to be installed as indicated.

NOTE:

Follow steps 1 and 2 as shown to cut the MIG braze slots.

- Mark the position and cut slots in the new side panel where the MIG braze slot welds are to be installed as indicated.

NOTE:

Follow steps 1 and 2 as shown to cut the MIG braze slots.

- Mark the position and cut slots in the new side panel where the MIG braze slot welds are to be installed as indicated.

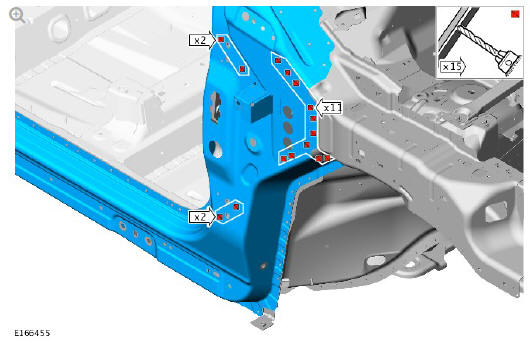

- Drill holes in the new side panel where the MIG plug welds are to be installed as indicated.

- Drill holes in the new side panel where the MIG plug welds are to be installed as indicated.

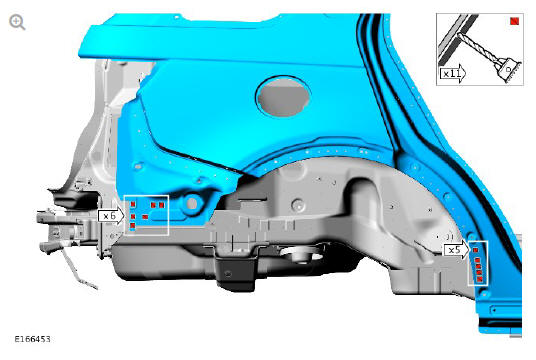

- Drill holes in the new side panel where the MIG plug welds are to be installed as indicated.

- Drill holes in the new side panel where the MIG plug welds are to be installed as indicated.

CAUTION:

This step requires the aid of another technician as the side panel is heavy.

- Remove the side panel.

- Deburr the drilled slots and holes.

- Clean and prepare the panel surfaces.

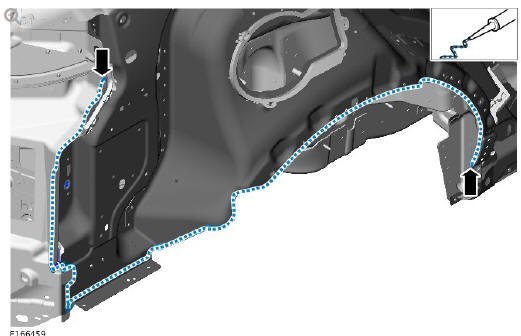

- Apply a 5 mm bead of Land Rover recommended sealer to the Noise, Vibration and Harshness (NVH) components as indicated.

- Apply a 5 mm bead of Land Rover recommended sealer to the NVH components as indicated.

- Apply a 5 mm bead of Land Rover recommended sealer to the NVH components as indicated.

- Apply a 5 mm bead of Land Rover recommended sealer to the vehicle assembly as indicated.

CAUTION:

This step requires the aid of another technician as the side panel is heavy.

- Offer up the new side panel and clamp into position. Check alignment, if correct, proceed to next step, if not, rectify and recheck before proceeding.

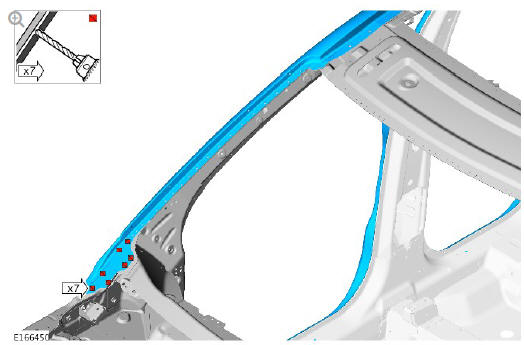

- Install the spot and MIG plug welds as indicated.

- Install the spot welds as indicated.

- Install the spot and MIG plug welds as indicated.

- Install the spot and MIG plug welds as indicated.

- Install the spot welds as indicated.

- Install the spot and MIG plug welds as indicated.

- Install the MIG braze slot welds as indicated.

- Install the MIG braze slot welds as indicated.

- Install the MIG braze slot welds as indicated.

- Install the MIG braze slot welds as indicated.

- Dress all welded joints.

- Apply a Land Rover recommended sealer and seal the panel flange edges of the MIG braze slot welds in the door aperture areas to prevent water ingress.

- Make sure that any open or exposed panel joints are correctly sealed.

- Make sure corrosion protection is applied to all areas affected by repair.

- The installation of associated panels and components is the reversal of removal procedure.

READ NEXT:

Side Panel Sheet

Metal Repairs

Rocker Panel and 'B'

Pillar Outer

Panel (G1770927) -

Removal

Side Panel Sheet

Metal Repairs

Rocker Panel and 'B'

Pillar Outer

Panel (G1770927) -

Removal

NOTE:

The rocker panel and B-pillar outer is installed in conjunction with:

Front bumper cover

Front fender

Front fender splash shield

Front door

Rear door

Front seat

Rear seat cushion

Cowl s

Side Panel Sheet

Metal Repairs

Rocker Panel and 'B'

Pillar Outer

Panel (G1770927) -

Installation

Side Panel Sheet

Metal Repairs

Rocker Panel and 'B'

Pillar Outer

Panel (G1770927) -

Installation

Installation

Dress the flanges where necessary.

Using the old rocker panel and B-pillar outer for reference measure,

mark and cut the new rocker panel and B-pillar outer where the

Metal Inert Gas

SEE MORE:

Planetary Gear Trains

Planetary Gear Trains

Gear set 1

Gearset 2

Gear set 3

Gear set 4

The planetary gear trains used on the 9HP48 transmission comprise four

planetary gear sets; GS1, GS2, GS3 and GS4.

Engine torque is transferred, via operation of single or combinations of

multiplate clutches, multiplate brakes and two dog clutches,

Anti-theft - Active / Operation

Anti-theft - Active / Operation

Operation

The Central Junction Box (CJB) automatically arms and disarms the active

anti-theft system when it operates the Central Locking System (CLS).

On vehicles without a volumetric sensor, only the perimeter mode is

available to monitor the hinged panels and the validity of the smart key.

When

© 2019-2025 Copyright www.lrdisc.com