Land Rover Discovery: Oil Seals

Never use a seal which has been improperly stored or handled.

- Take great care when removing old seals that the sealing surfaces and seal housing are not damaged.

- Carefully examine seal before installing to make sure that it is clean and undamaged.

- Make sure that the surface on which the seal is to run and also the seal housing is clean and free from burrs or scratches. Renew the component if the sealing surface cannot be restored.

- Special tools and protection sleeves are provided for installing the majority of seals and must be used when specified.

- Many seals are now coated with a protective wax and DO NOT need to be lubricated prior to installing. Always check the relevant repair procedure which will state if a seal must be installed dry. Never touch these seals with oily hands as the oil will contaminate the protective coating and affect the sealing properties of the seal; also, make sure that installing tools and protection sleeves are free from oil and grease. Seals which must be lubricated prior to installing should have the recommended lubricant applied to the areas specified in the repair procedure.

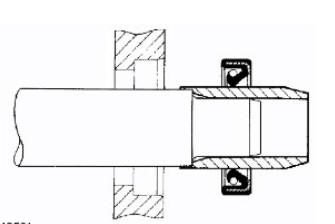

- Make sure that a seal is installed the correct way round. For example, the lip of the seal must face towards the lubricant which it is sealing.

- When installing an oil seal, make sure that it is positioned square to shaft and housing. Where the seal is to be installed to a housing prior to installing over a shaft, take care not to allow the weight of an unsupported shaft to rest on the seal.

- Always use the recommended special tool and protection sleeve to install an oil seal. If no tool is specified, use a suitable mandrel approximately 0.4 mm (0.015 in) smaller than the outside diameter of the seal. Use adhesive tape on the shaft to protect the sealing lip of the seal.

.21.jpg)

- Press or drift the seal in to the depth of its housing if the housing is shouldered or flush with the face of the housing where no shoulder is provided. Make sure that the seal is not tilted in the housing when it is installed.

READ NEXT:

Supplementary Restraint System ( SRS ) Precautions

Supplementary Restraint System ( SRS ) Precautions

WARNING:

Do not install rear facing child seats in the front passenger seat.

The SRS contains components which are potentially hazardous to service

personnel if not handled correctly. The following gu

Airbag and Pre-tensioner Deployment

Airbag and Pre-tensioner Deployment

WARNING:

During deployment parts of the airbag module become hot enough

to burn you. Wait 30 minutes after deployment before touching the

airbag module.

Deployment procedures and precautions as detail

Front Airbag Deployment -

Driver and Passenger

Front Airbag Deployment -

Driver and Passenger

CAUTION:

If the front airbags are deployed, the following components must be

replaced:

Driver airbag module

Steering wheel

Passenger airbag module

Instrument panel

Fly leads (where applicable) c

SEE MORE:

Exterior Trim and Ornamentation

Rear Door

Lower Moulding (G1796253)

/Removal and Installation

Exterior Trim and Ornamentation

Rear Door

Lower Moulding (G1796253)

/Removal and Installation

PART(S)

REMOVAL

CAUTION:

Make sure to protect the paintwork.

NOTES:

Removal steps in this procedure may contain installation details.

RH illustration show LH is similar.

CAUTION:

Do not use tools during this operation, removal of the

component(s) must be carried out by hand.

NOTE:

Discard the r

Selective Catalyst Reduction

(SCR) Components - EU6 only

Selective Catalyst Reduction

(SCR) Components - EU6 only

Diesel Exhaust Fluid (DEF) tank module

Diesel Exhaust Fluid (DEF) level sensor

Diesel Exhaust Fluid (DEF) tank module electrical connection

Diesel Exhaust Fluid (DEF) pressure line connection

Diesel Exhaust Fluid (DEF) injection pump electrical connection

Diesel Exhaust Fluid (DEF) heater el

© 2019-2025 Copyright www.lrdisc.com