Land Rover Discovery: Transmission Transaxle Cooling Description and Operation

COMPONENT LOCATION - ZF 9HP48 TRANSMISSION TD4 2.2L DIESEL

- Automatic Transmission Fluid (ATF) cooler

COMPONENT LOCATION - ZF 9HP48 TRANSMISSION GTDi 2.0L PETROL

- Automatic Transmission Fluid (ATF) cooler

OVERVIEW

The ZF 9HP48 automatic transmission uses an external ATF (automatic transmission fluid) cooler to reduce the temperature of the transmission fluid.

A plate type cooler uses engine coolant to reduce the ATF temperature.

DESCRIPTION

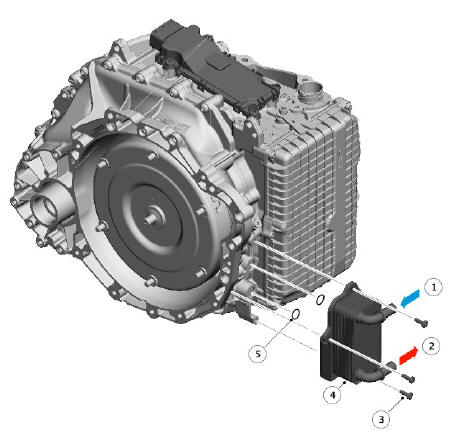

- Engine coolant inlet

- Engine coolant outlet

- Torx screw (3 off)

- ATF Cooler

- Seals

The ATF cooler is located on the transmission main casing. The ATF cooler is an aluminium housing comprising louvred fins and plates. The plates allow a cross-flow of ATF and engine coolant through the ATF cooler. The plates are immersed in the engine coolant from the 'cold' side of the radiator which provides cooling of the ATF by the temperature differential between the ATF and the engine coolant.

The engine cooling system has a low temperature zone in the top third of the radiator. The engine coolant flow through this section of the radiator is restricted by the ATF cooler. Therefore the engine coolant has a slower flow rate across the cooling tubes of this section of the radiator. This cools the engine coolant more than the lower part of the radiator and consequently provides increased cooling of the ATF.

The ATF cooler has an integral thermostatic valve, which controls the ATF flow through the cooler. Flow is restricted to improve ATF warm-up time.

The thermostatic valve is closed at temperatures of 78ºC (172ºF) and below, starts to open at temperatures of between 78 and 84ºC (172 and 183ºF) and is fully open at temperatures of 96ºC (204ºF) and higher.

OPERATION

AUTOMATIC TRANSMISSION FLUID (ATF) COOLER

Engine coolant is circulated through the ATF cooler which cools the ATF flowing through the ATF cooler by the temperature differential between the two fluids.

Transmission transaxle cooling diagnosis and testing

PRINCIPLES OF OPERATION

For a detailed description of the Automatic Transmission Cooling system, refer to the relevant Description and Operation section in the workshop manual. REFER to: Transmission Cooling (307-02 Transmission/Transaxle Cooling, Description and Operation).

INSPECTION AND VERIFICATION

CAUTION:

Diagnosis by substitution from a donor vehicle is NOT acceptable.

Substitution of control modules does not guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

- If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new module/component.

- When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with an up-todate calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into account.

- Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

- Verify the customer concern

- Visually inspect for obvious signs of damage and system integrity

Visual Inspection

- If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step

- If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

- Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific customer complaint and carry out the recommendations as required

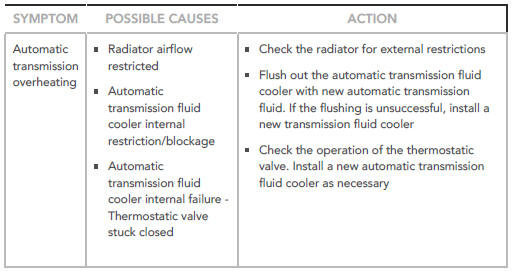

SYMPTOM CHART

SYMPTOM:

Automatic transmission overheating

POSSIBLE CAUSES:

- Radiator airflow restricted

- Automatic transmission fluid cooler internal restriction/blockage

- Automatic transmission fluid cooler internal failure - Thermostatic valve stuck closed

ACTION:

- Check the radiator for external restrictions

- Flush out the automatic transmission fluid cooler with new automatic transmission fluid. If the flushing is unsuccessful, install a new transmission fluid cooler

- Check the operation of the thermostatic valve. Install a new automatic transmission fluid cooler as necessary

DTC INDEX

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00. REFER to: Diagnostic Trouble Code Index - DTC: Transmission Control Module (TCM) (100-00 General Information, Description and Operation).

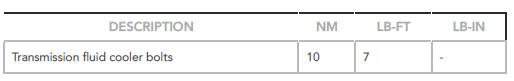

Transmission transaxle cooling specifications

Torque Specifications